Before

After

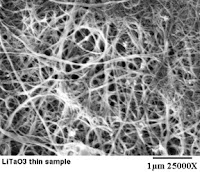

Before and after electron microscope images of a pyroelectric detector coated with single-walled nanotubes (SWNTs) visually demonstrate the effect of the laser cleaning process. In addition, the SWNTs look visibly blacker after laser treatment, suggesting less graphitic material and increased porosity. (Image and Caption Source: NIST)Before carbon nanotubes can fulfill their promise as ultrastrong fibers, electrical wires in molecular devices, or hydrogen storage components for fuel cells, better methods are needed for purifying raw nanotube materials. Researchers at the National Institute of Standards and Technology (NIST) and the National Renewable Energy Laboratory (NREL, Golden, Colo.), have taken a step toward this goal by demonstrating a simple method of cleaning nanotubes by zapping them with carefully calibrated laser pulses.

“Controlling and determining tube type is sort of the holy grail right now with carbon nanotubes. Purity is a key variable,” says NIST physicist John Lehman, who leads the research. “Over the last 15 years there’s been lots of promise, but when you buy some material you realize that a good percentage of it is not quite what you hoped.

"Anyone who thinks they’re going into business with nanotubes will realize that purification is an important—and expensive—step. There is a lot of work to be done.”

When carbon nanotubes—the cylindrical form of the fullerene family—are synthesized by any of several processes, a significant amount of contaminants such as soot, graphite and other impurities also is formed. Purifying the product is an important issue for commercial application of nanotubes. In a forthcoming issue of Chemical Physics Letters*, the NIST/NREL team describes how pulses from an excimer laser greatly reduce the amount of carbon impurities in a sample of bulk carbon single-walled nanotubes, without destroying tubes. Both visual examination and quantitative measurements of material structure and composition verify that the resulting sample is “cleaner.” The exact cleaning process may need to be slightly modified depending on how the nanotubes are made, the authors note. But the general approach is simpler and less costly than conventional “wet chemistry” processes, which can damage the tubes and also require removal of solvents afterwards.

After

Before and after electron microscope images of a pyroelectric detector coated with single-walled nanotubes (SWNTs) visually demonstrate the effect of the laser cleaning process. In addition, the SWNTs look visibly blacker after laser treatment, suggesting less graphitic material and increased porosity. (Image and Caption Source: NIST)

“Controlling and determining tube type is sort of the holy grail right now with carbon nanotubes. Purity is a key variable,” says NIST physicist John Lehman, who leads the research. “Over the last 15 years there’s been lots of promise, but when you buy some material you realize that a good percentage of it is not quite what you hoped.

"Anyone who thinks they’re going into business with nanotubes will realize that purification is an important—and expensive—step. There is a lot of work to be done.”

When carbon nanotubes—the cylindrical form of the fullerene family—are synthesized by any of several processes, a significant amount of contaminants such as soot, graphite and other impurities also is formed. Purifying the product is an important issue for commercial application of nanotubes. In a forthcoming issue of Chemical Physics Letters*, the NIST/NREL team describes how pulses from an excimer laser greatly reduce the amount of carbon impurities in a sample of bulk carbon single-walled nanotubes, without destroying tubes. Both visual examination and quantitative measurements of material structure and composition verify that the resulting sample is “cleaner.” The exact cleaning process may need to be slightly modified depending on how the nanotubes are made, the authors note. But the general approach is simpler and less costly than conventional “wet chemistry” processes, which can damage the tubes and also require removal of solvents afterwards.

Labels: carbon nanotube, CNT, nanotechnology

Latest Space Elevator Headlines by Google News™

Latest Space Elevator Headlines by Google News™